Investment Opportunity in Energy Efficiency

—

As we’ve all observed, the idea of energy efficiency generally often lacks sex appeal. The concept of the negawatt, i.e., “the cheapest watt-hour of energy is the one you don’t use,” is normally invisible; it may be insulation tucked inside the walls of your house, or the aluminum components under the paint of the car you drive. Yet those of us who are searching for a sustainable approach to providing energy to the world’s growing and increasingly power-hungry civilization regard efficiency as the “low-hanging fruit.”

Sure, we can try to replace fossil fuels with solar and wind, and obviously that’s a good idea, but the most practical opportunities to keep the world’s carbon in the ground and out of our atmosphere reside in simply reducing the amount of energy we’re consuming on a minute to minute basis.

This month’s cleantech business deals with this exact notion, in particular, how we can provide heat where it’s needed in a far more efficient fashion that ever before. Think for a minute about the “radiant” heat from our floors (which is really conduction and convection, rather than radiant), or the heat we provide to our automobile seats, and how these processes are commonly achieved: metal wires of a given resistance that, when a voltage is applied, enable a current to flow that is obstructed by the resistance and causes friction that generates heat.

Well, how efficient is that? Consider the diagrams and the discussion below, and then use them to arrive at the answer: not very.

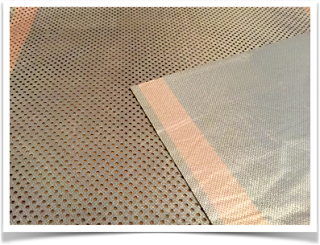

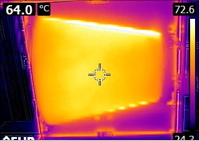

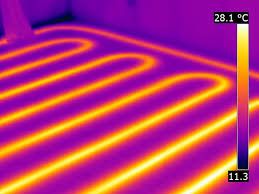

Enter a company called LaminaHeat, whose patent-pending breakthrough offers a sheet of material made of non-metallic carbon fiber-based resistive heating; a proprietary mix of cut-to-size carbon fibers in a veil matrix that heats with almost 100% even distribution. Check this out:

Floor Heating

How does LaminaHeat in traditional floor heating compare to standard hydronic systems where the water is heated by either gas or oil furnace?

This deep embedding not only delays the time the heat needs to reach the floor surface, but it also causes a significant amount of heat loss in the floor structure as well.

Based on the 1st Law of Thermodynamics, the LaminaHeat PowerFilm will be 2.2 times more efficient due to the fact of being a full surface heater. Water pipes have 4-5 times less surface area than LaminaHeat PowerFilm to generate heat—hence the deficiency.

The LaminaHeat PowerFilm is less than 50 mm thick and can be embedded directly into a range of industry standard matrices like PVC, laminate or acoustical surfaces instead of being buried in 150 mm of concrete like hydronic pipes. Furthermore, the product is so thin that it can be embedded into the above-mentioned matrices during their production processes without change in fin

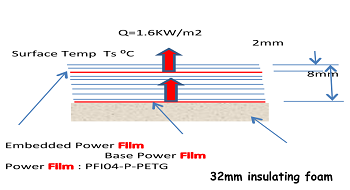

Another key advantage of LaminaHeat is the ability to position the heating element as close to the radiating surface as possible without having any impact on the visual surface finish. The sample calculation on the right shows LaminaHeat just 2 mm below surface in an 8 mm thick floor laminate. Bringing the heating element so close to the radiating surface causes the heating efficiency to increase again by a

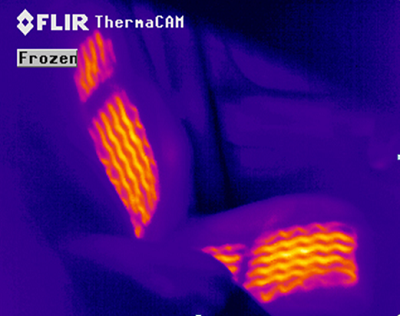

Car seat heating:

LaminaHeat in contrast:

• Will not overheat – designed to not exceed 40° C

• 100% of surface heats up at the same time

• Heat is placed directly underneath the textile or leather surface for optimal heating comfort

• Tier 1 supplier can incorporate LaminaHeat in any of his customer desired surface finishes

Additional markets….

Industrial

- Molds, tools, vacuum bags

- Heated presses

- Localized heated flooring on shop floor and manufacturing plants

Comfort

- Garments (Motor bikes, Hunting, Expeditions, Winter gear for elderly people, e.g.)

- Seating (Stadium & Events)

- Building Industry (wall and ceiling)

- Dry Sauna, Countertops, bath tubs, e.g.

- Furniture (personalized heated cubicles, e.g.)

Safety

- Building Industry (de-icing of critical walkways, drive ways, ice dam prevention on roofs)

- Infrastructure (Frost/Ice prevention on bridges, roads, runways, rotor blades on wind farms)

- Transportation (de-icing of truck and bus roofs, de-icing of aircraft wings

Health

- Medical equipment (heated patient tables [CT, MRI, X-Ray], hypothermia patients, incubators)

- Medical support (e.g., heated massage tables)

- Heated mattresses for hospitals and retirement homes

- Hypothermia recovery blankets

Investment Opportunity:

In order to expand its operations, build out its R&D center and build its relationships with OEM customers, the company needs to raise $1.7 million, in exchange for a substantial equity stake. As always, please let me know if you’re interested, and I’ll connect you directly with the executive team.

Whilst the product clearly has advantages over wire based resistive heating – particularly in regards to safety, I cannot support some of the claims made in the article.

Claim 1

“Based on the 1st Law of Thermodynamics, the LaminaHeat PowerFilm will be 2.2 times more efficient due to the fact of being a full surface heater. Water pipes have 4-5 times less surface area than LaminaHeat PowerFilm to generate heat—hence the deficiency.”

Criticism

That would depend on the levels of heat loss into and through the floor. If the water based system were constructed over a thick layer of rigid insulation with metallic coatings to reflect infra red, then losses through the floor would be negligible. There would in effect be almost no difference in the overall heating efficiency

Where there is a difference is in speed of response – the LaminaHeat product can respond in minutes, whilst the water based system takes hours to respond. This can save considerable amounts of energy as the LaminaHeat system can be switched off or to a much lower setting when the building is unoccupied.

On the other hand, in areas with cold nights and warm sunny days, the water based system might score highly as the thermal mass of the floor would in effect store heat from daytime sunshine to warm the room through the evening.

Claim 2

“Bringing the heating element so close to the radiating surface causes the heating efficiency to increase again by a f photo L2A_zpscwojicl9.pngactor of 1.34”;

Criticism

Again, this relates to speed and responsiveness rather than to energy efficiency and is in my view a spurious argument – especially in adequate underfloor insulation is used

(In the article, an image refers to 12 mm of foam – that is laughably inadequate, and is less than a third of the minimum that UK builders are currently required by building regulations to specify).

Also to be considered is that the LaminaHeat system is based on resistive use of electricity which on a typical US electricity source mix has significantly higher emissions per kWh than gas, so that if the choice were to be between water based underfloor heating using a gas boiler, or a LaminaHeat system, then it is likely that the gas system would result in lower emissions.

Should the water based system be using an air to water heat pump in a temperate area, or a ground source heat pump in an area with cold winters, the water based system with sufficient under floor insulation would be more efficient in emission terms than either a gas boiler, or LaminaHeat system.

Also to be considered – both of these systems are likely to be specified in new build rather than retrofit applications. In this context, it would make far more sense to build to PassiveHaus standards of insulation with mechanical heat recovery ventilation which in many regions would come close to eliminating the need for active heating altogether. In a Passivehaus construction, each room typically has a small electric heater of 200W to 300W for occasional use when passive heat gains are insufficient to maintain comfortable conditions.

You make some good points here. The 12 mm figure turns out to be a typo; it’s 32 mm; I made the changes above.