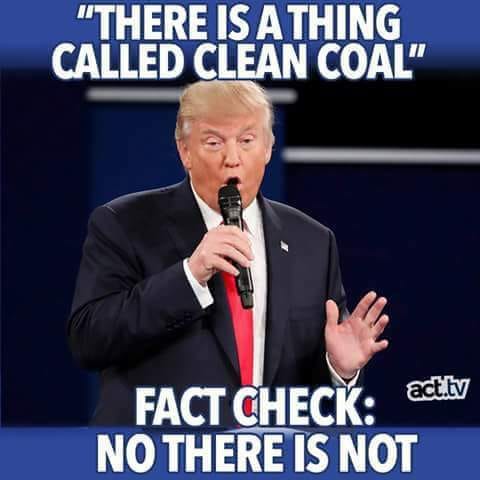

Is Clean Coal a “Thing?”

And, to be fair, clean coal actually does exist in the physical universe, not unlike ocean current energy. Yes, it’s of no value due to the fact that it’s outrageously expensive compared to competitive approaches, but it’s very much a thing in the usual sense of the word.

I’m afraid I don’t follow you when you say “clean coal actually does exist in the physical universe, not unlike ocean current energy.”

I think the only thing in the physical universe that would equate to “clean coal” would be “diamond”… which has plenty of value, just not as a source of stored energy. Also, the only “ocean current energy” that I am aware of is seen in wholly untapped natural power within the Earth’s thermohaline circulation.

Perhaps you meant to say “theoretically could exist”? Or are there small projects of both that I am unaware of?

I meant to say that there actually are attempts at CCS, and there are also attempts at ocean current energy. Both are doomed to failure, but they do exist.

Personally I think that Ocean current energy will survive, but only in coastal countries with lots of potential like Canada’s Bay of Fundy. However, CCS will definitely fail because it is too costly.

Craig,

As I pointed out in my main repsponse, “Clean(er) Coal” technology already exists, and those who deny the potential are either being deliberately obtuse,politically invested, conflicted by loyalties to other technologies, or just plain ignorant and too lazy to keep up to date with developments.

Denial and opposition to Clean(er) Coal technology seems confined to a certain type of environmentalist existing solely in the US and western nations.

Economic competition from cheap and plentiful Natural Gas will soon disappear once the full impact of rising Asian and European for demand LPG affe3cts the market price.

Your knowledge of “CCS” seems to be stuck somewhere around 2007. It’s really time you acquainted yourself with the latest developments.

CCS has come a long way since 2007, it no longer means just burying pollutant emission in in the ground after scrubbing down a power plant !

Researchers like Dr. Liang-Shih Fan a Professor of Chemical and Biomolecular Engineering, have developed, field tested and are in the beta stage of commercializing a process called chemical looping. Dr Fan believes this method provides a way use coal without generating significant amounts of carbon dioxide (CO2) or other pollutants. Coal-direct chemical looping allows plants to burn coal without emitting pollution.

Chemical looping burns fossil fuels and biomass in pressurized reactors without oxygen in the air. Metal oxide in the reactor provides oxygen for the combustion, which then “loops” the gases through different chambers, producing heat. At a basic level, the method burns oxygen, while holding onto carbon, and the heat generated during the combustion enables steam turbines to generate electricity. The process is capable of converting fuels into energy or other chemical products, while emitting less than one percent of the CO2 the fuels would otherwise produce.

The revolutionary aspect of this technology avoids the problems of previous concepts of “clean(er) coal” where carbon capture only after combustion.

Dr. Fan, along with many other research projects now becoming tangible reality, introduces a radically new version of “clean(er) coal avoiding the production of CO2 at all. His process eliminates the costs associated with regulating, monitoring, and cleaning up after energy production by making the process itself cleaner.

By capturing over 99 percent of the CO2 normally produced as coal is burned, the chemical looping process emits virtually no pollutants into the atmosphere, while recycling any byproducts of the reaction into other uses.

One of he more imaginative new owners of a Coal Generating plant is exploring a multi-purpose use for his facility.

His plan envisages more than simply burning coal to produce electricity, his plant would be a production centre for the development and manufacture of a wide range of Coal based industries.

The company has already built a facility at the plant to convert coal to rare earth materials, for batteries, magnets, electronics and military products.

Renovating an old disused part of the plant into a state-of-the-art manufacturing facility to manufacture carbon fiber for sporting goods, aerospace applications, wind turbine blades (irony:))and other specialty applications.

Currently, most carbon fibre is produced by synthetic polyacrylonitrile. It’s believed that by substituting Coal the cost of the process could be halved and molecular quality improved. The demand for carbon fibre is growing rapidly.

The point I’m making is “Clean(er) Coal” technology is relatively new and neglected for a long time in the excitement of renewable sources of energy.

Why is it so hard to believe that given time and funding, clean(er) coal technology won’t expand just as quickly ?

In fact, it already is,..just not in the US ! In China, India, South Korea, even Indonesia, Clean(er) coal technology is becoming economically affordable.

Thanks to the neglect and animosity by the Obama administration, and fanatical arrogance of some US environmental advocates, the US has lost the lead in the most most important technology able to dramatically and quickly reduce global emissions.

The arising technologies aren’t just attempts ! They are taking place all around you. (well, maybe not in the NYT,CNN or Guardian) it just takes a little research and a willingness to be open minded.

Craig,

It always saddens and baffles me why, like a lot of people, you refuse to accept Clean(er) coal technology is not only feasible, but already a reality.

The development of various technologies transforming the use of coal in environmentally beneficial ways is occurring at a speed which is truly astonishing. Research and development of Clean(er) coal technologies has been until very recently conducted largely in countries like India, the Peoples Republic of China and South Korea.

The US is major Coal using nation with massive natural reserves( more than 300 years of known reserves). The US is usually one of the most technically innovative and inventive nations when it comes to introducing new technology, so what why not coal ?

IMHO, Coal like Nuclear suffers from a bad image. Coal is a very old form of industrial energy, with almost no attractive or sexy attributes, except producing energy.

Coal is inherently dirty. It even looks dirty ! From childhood we have all grown up associating the worst images of life during the industrial revolution as caused by the dirt and grime of coal smoke, dirty coal mining towns, grim union battles fought out in grey poverty stricken slums. The horrible siren of the pit head summoning miners to a mine disaster implants strongly emotive negative images.

Coal, often quite rightly, is associated with environmental destruction. Images of huge scared desecrated landscapes full of abandoned machinery, slurry and dangerous empty pits are vividly depicted in thousands of films, TV and books.

Ernest scientists and romantically portrayed doctors condemning coal mining, noble environmental advocates eager to battle the monster of Coal make for good dramatics fiction.

The coal industry has no friends, not even the other fossil fuel producers since natural gas is a keen competitor !

With the rise of popular environmentalism, and shiny new “sexy” technologies like Wind and Solar, coupled by a resurgent Natural Gas industry reborn as a result of hydraulic producing cleaner, cheaper and more versatile fuel the Coal industry fell into a slump.

Who could prefer coal ? Who wanted to be associated with such a dirty, old fashioned and more importantly, uneconomic industry.

By 2015, the US and European coal industries were in seemingly terminal decline and decay.

Lack of investment, rising costs and falling prices, determined environmental and government opposition, all conspired to render the Coal industry stagnant and moribund.

The US coal industry wasn’t helped by being dominated by pugnacious, but short sighted leaders like Robert E. Murray CEO of Murray Energy Corporation, or the old fashioned boards of other Coal producers.

Yet, Coal remains 32% of US energy and more than 40% of global energy. Coal provides “power on demand”, reliably and safely.

The focus on reducing Climate Change and carbon emissions should have tolled the end of the Coal industry. Curiously, those environmental concerns may well be the savior of the Coal industry! Coal is responsible for 90% of the SO2 emissions, 70% of dust emissions, 67% of NOx emissions, and 70% of CO2 emissions.

Each year the global demand for coal increases. The developing world is hungry for industrial energy which renewable sources are unable to supply. The choice is no longer whether or not the Coal industry will expand, but what sort of coal industry will emerge. The International Energy Agency estimates coal will remain the biggest source of electricity generation until at least 2050, and consumption in South East Asia, India and Africa is projected to rise dramatically. China will remain the largest consumer in the world.

In just two years, the US coal industry has received an enormous boost in confidence from President Trump’s termination of the Obama era “war on coal”. The President’s initiatives have created a revolution within the industry and attracted investment back into Clean Coal research and development.

Realistic environmentalists and climate scientists have started to recognize only effective clean coal technology can rapidly reduce global emissions on a meaningful scale. Further savings can be achieved in allied heavily polluting industries as by products for recycling coal emissions and waste material.

The cost of Clean(er) coal is being constantly reduced as would be expected with the ongoing refinement of technological progress and adoption.

The US has lagged behind, mainly due to a political process and the discovery of cheap natural gas.

In China, India and other nations more than 100 Coal fired plants are already equipped with Ultra-supercritical technology. In the US only a handful of plants possess even the older, far less efficient supercritical technology, most are just old subcritical installations.

India, China, Indonesia are beginning to istall coal pulverisation and large-scale fluidised bed boilers.

Coal-to-chemicals industry is already investing in coal pyrolysis, gasification, and carbon capture and storage (CCS) technologies. CCS has the capacity to trap and store up to 90% of CO2 emissions from electricity generation and industrial processes in geological reservoirs such as depleted oil and gas fields and un-mineable coal seams.

Most critic’s of coal are not aware that adding CCS technology to ultra-supercritical plants coast only a fraction of the costs involved installing such technology to subcritical or supercritical plants.

India is probably the only nation rivaling China in the race for Clean Coal technology. India’s electricity is 72% Coal-fired. The Indian government has been incentivizing Clean(er) coal technology. One Indian Utility has been capturing carbon from its coal-powered boiler to make baking soda!

The Indian government’s high efficiency, low emission (HELE)program will see every power plant converted to ultra-supercritical boilers and CCS technology by 2025.

The world’s third-largest coal producer, Australia, expects to meet its Paris climate goals by replacing existing coal power stations with ultra-supercritical plants and making CCS products available to the mining industry, thereby reducing carbon emissions by 28%.

Japan, the world’s fourth-largest coal consumer, installed two HELE coal units at the Isogo thermal power station with an efficiency rate of 68%. These were constructed to compensate for the loss of nuclear power capacity after the 2011 earthquake. Japan is already very advanced in using Coal waste for building products.

Meanwhile back in the USA, a host of derision has been heaped on Dr Xianming Shi,associate professor in WSU’s Department of Civil and Environmental Engineering, and graduate student Gang Xurea for creating a sustainable alternative to traditional concrete using coal fly ash, a waste product of coal-based electricity generation.

Their discovery tackles two major environmental problems at once by making use of coal production waste and by significantly reducing the environmental impact of concrete production.

The product reduces energy demand, greenhouse emissions, by creating a strong, durable concrete using fly ash as a binder thereby eliminating environmentally intensive cement.

Production of traditional concrete, which is made by combining cement with sand and gravel, contributes between five and eight percent of greenhouse gas emissions worldwide. That’s because cement, the key ingredient in concrete, requires high temperatures and a tremendous amount of energy to produce.

Fly ash, the material that remains after coal dust is burned, meanwhile has become a significant waste management issue in the United States. More than 50 percent of fly ash ends up in landfills, where it can easily leach into the nearby environment.

While some researchers have used fly ash in concrete, they haven’t been able to eliminate the intense heating methods that are traditionally needed to make a strong material.

This new production method does not require heating or the use of any cement.The process utilizes nano-sized materials to engineer concrete at the molecular level using graphene oxide, a recently discovered nanomaterial, to manipulate the reaction of fly ash with water and turn the activated fly ash into a strong cement-like material.

The graphene oxide rearranges atoms and molecules in a solution of fly ash and chemical activators like sodium silicate and calcium oxide. The process creates a calcium-aluminate-silicate-hydrate molecule chain with strongly bonded atoms that form an inorganic polymer network more durable than (hydrated) cement.

The resulting ‘concrete’ can be pervious if required, allowing water can pass through it to replenish groundwater and to mitigate flooding potential.

The torrent of rabid opposition to this invention in both conventional and social media, has been frightening. A large group of the WSU student body gathered to demand the end of the project and the removal the researchers for being stooges of the Coal industry !

(The research is funded by the US Dept of transport)

A Californian company called Calera has developed a process of making calcium carbonate cement.

While the process wouldn’t eliminate all CO2 emissions, it would reverse the equation. For every ton of cement produced, half a ton of CO2,sequestered using a by product of coal or gas fired electricity production.

Calera is not alone, all over the world scientist and engineers are beginning to see the potential in Coal fired electricity generation CCS as a source of raw materials.

In Russia, waste coal recycling technology is producing of glass, bricks burning and raw material for ceramics manufacture, involving allows coal residues to be extracted from argillites by pneumatic waste classification and stable ceramic raw material.

The complex processing of waste coal provides a significant expansion in economic raw materials while improving the environment.

Coal by products include, creosote oil, naphthalene, phenol, and benzene. Ammonia gas recovered from coke ovens is used to manufacture ammonia salts, nitric acid and agricultural fertilizers. Thousands more products contain coal or coal by-products as components, soap, aspirins, solvents, dyes, plastics and fibres, rayon, nylon and surgical gauze.

Coal is also an essential ingredient in the production of specialist products like, activated carbon( used in filters for water and air purification and in kidney dialysis machine)

Carbon fibre, an extremely strong but light weight reinforcement material used in construction, mountain bikes and tennis rackets.

Silicon metal, used to produce silicones and silanes, which are in turn used to make lubricants, water repellents, resins, cosmetics, hair shampoos and toothpaste

Why would any committed environmentalist decry the value of advanced coal technology, without serious research or comprehensive knowledge?

Craig,

You are fond of quoting scientists, well here’s a scientist with a positive, pragmatic, sensible approach to the problems of climate change. (the Professor address was even published in the Guradian :))

Australia’s chief scientist,Dr Alan Finkel, responded to the Intergovernmental Panel on Climate Change’s report, by observing, ” the question facing the global energy future is not about renewables versus coal, but how best to create an economic emissions reduction strategy”.

Dr Finkel went on saying, ” US, European and Australian climate idiocracy must end, and there’s no time to waste debating pro-and anti-coal stances but using all available technologies to create the best outcome. We’ve got to focus on outcomes,The outcome is atmospheric emissions. We should use whatever underlying technology are suitable for that”

Dr Finkel emphasized ” “People, including scientists, activists, politicians and the media have painted themselves into an anti-coal corner or a pro-coal corner, but the only question of relevance is to look at the atmospheric emissions and pursue every and all technologies with the capacity to reduce emissions”.

Dr Finkel continued on this theme observing , “We need to look at things like coal-fired power with carbon capture and advanced clean coal technology, the issue is not as black and white as was being presented. This is no time for fatalism, all decision-makers be they in government, industry or the community must listen to the science”.

“We have to look squarely at the goal of a zero-emissions planet, then work out how to get there while maximizing our economic growth, It requires an orderly transition, and that transition will have to be managed over several decades”.

“The IPCC has made the same point, not just for Australia, but for the world,” he said in address adding, “We have in Australia the abundant resources required to produce clean hydrogen for the global market at a competitive price, on either of the two viable pathways, splitting water using solar and wind electricity, or deriving hydrogen from natural gas and coal in combination with carbon capture and sequestration, and other advanced clean coaltechnologies.

“Building an export hydrogen industry will be a major undertaking. But it will also bring jobs and infrastructure development, largely in regional communities, for decades.

“So the scale of the task is all the more reason to press on today, at the same time as we press on with mining lithium for batteries, clearing the path for electric vehicles, planning more carbon-efficient cities, and so much more.

His address was entitled “Forget about Coal Wars, Save the Planet”.

Alan Simon Finkel AO FAA FTSE is Australia’s Chief Scientist. An Australian neuroscientist, engineer, entrepreneur and philanthropist, he served as Chancellor of Australia’s largest university, Monash University, between 2008-2016.

Now, why can’t we all be as positive, calm and realistic as Dr Alan Finkel ?